DOWNSIZING Technology

By Mino’s unique downsizing technology, our company is able to cast heavier parts on smaller die cast machines. This reduces the cost of casting parts.

[For example]

Part size = 210 × 310 ×50(mm)

Usually, for this part, we use 850 ton machines.

↓

But, by utilizing our downsizing technology and computing casting tolerance we are able to

cast this part in 350 ton machines.

This picture is an example of a typical 850 ton

part made with a 350 ton die casting machine.

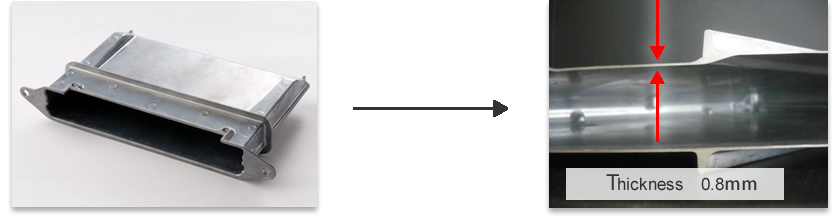

ULTRA THIN DIE CASTING Technology

Other specialities of Mino are creating thinner walls in castings and making castings more light in weight.

Because of this we can reduce material fees.

[For example]

ECU CASE Cut Model

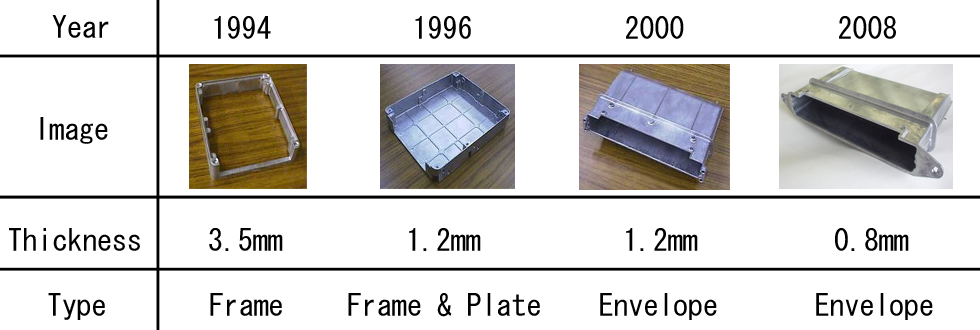

History of ULTRA THIN DIE CASTING in MINO

【History of ULTRA THIN DIE CASTING in MINO】

The history of our technology involves the challenge of maing thin die-casting products.

The frame shape of ECU cases before 1994 were 3.5 mm thin.

In 1996, depicted below, we started mass production of our 1.2mm box shape ECU cases.

We succeeded in mass production of 1.2mm bag shape ECU cases during 2002.

After 2006 we started making 0.8mm bag shape ECU cases.

Integrated manufacture Technology

Our company has an integrated production line from casting to machining.

Our die-casting process and machining process are run on one production line to prevent excess inventory

and we use the process of automation to make products at high levels of efficiency.

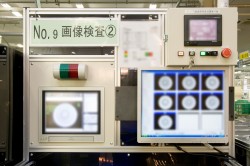

We use 3D machines, X-ray inspections, and image processing systems to ensure quality assurance.